Bushings

Bushings

A bushing’s main function is the physical separation of the conductors from each other and from the ground. Other functions include providing mechanical support, heat dissipation and environmental protection of the conductors.

The advantage of ceramics over many organic materials lies in its great chemical stability and durability when exposed to high temperatures, humidity, or contaminated media, without degrading its chemical properties, mechanical to dielectric.

Prolec Celeco® is the largest manufacturer of bushings in Mexico and the only manufacturer of 34.5 kV class bushings with a lightning impulse resistance greater than 250 kV BIL. These insulators fulfill the function of mechanically holding the conductor, keeping it isolated from ground and other conductors. They must withstand the mechanical load that the conductor transmits through them. They must also electrically insulate the conductor, as well as withstand voltage under normal, abnormal and surge conditions.

Tension must be supported by the insulating material itself, as well as by its surface and the air surrounding the insulator. Electrical failure of air is called arcing, and the insulator is designed so that this failure is much more likely than the puncture of the solid insulator.

Low Voltage Bushings

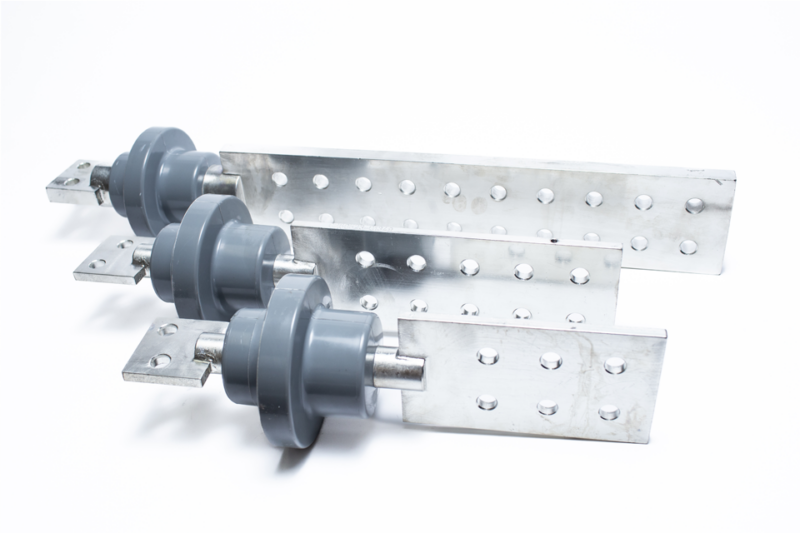

- Porcelain Low Voltage Bushings: 1 kV, up to 4,500 A

- Polymeric Low Voltage Bushings: 1 kV up to 1,250 A

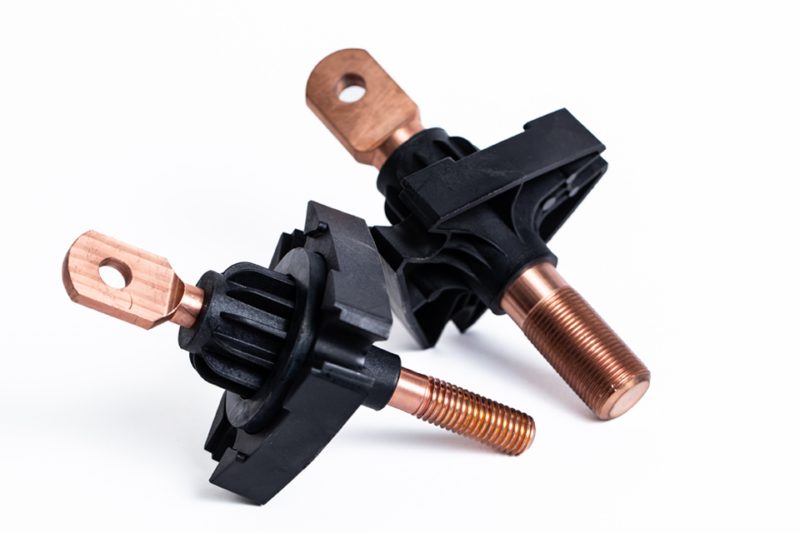

- Triclamp (Secondary Stud): 1.2 kV – 830 A/1,500 A/2,200 A

- Low Voltage Epoxy Bushings: Up to 4,515 A

High Voltage Bushings

- Porcelain High Voltage Bushings: Up to 34.5 kV

- Porcelain Insulators: Up to 69 kV

- Pedestal Bushings (Well Type): 34.5 kV

- Inserts (Loadbreak): 15 kV – 25 kV, 200 A

- Integral (Deadbreak): 25 kV – 35 kV, 600 A

Manufacturing Facility

Our low voltage bushings are manufactured at Prolec Celeco located in Monterrey, Mexico, supporting both American continents’ distribution transformer markets.